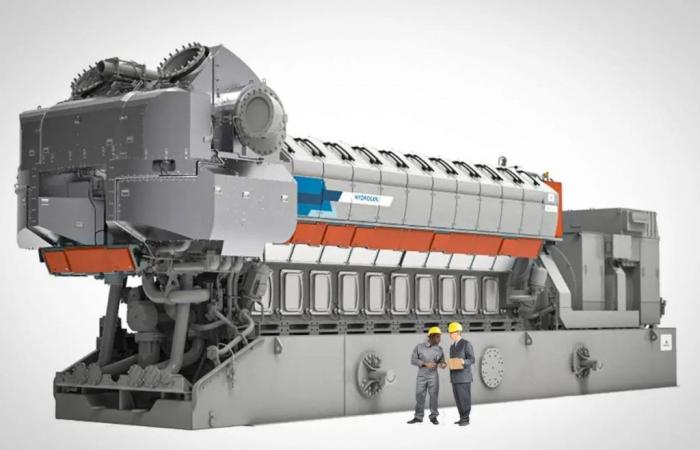

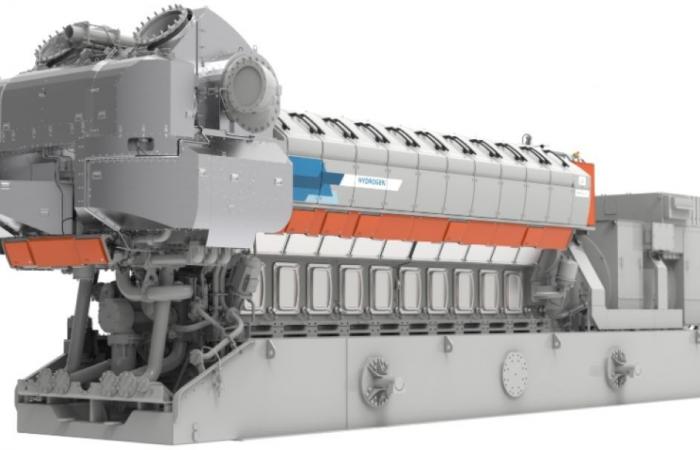

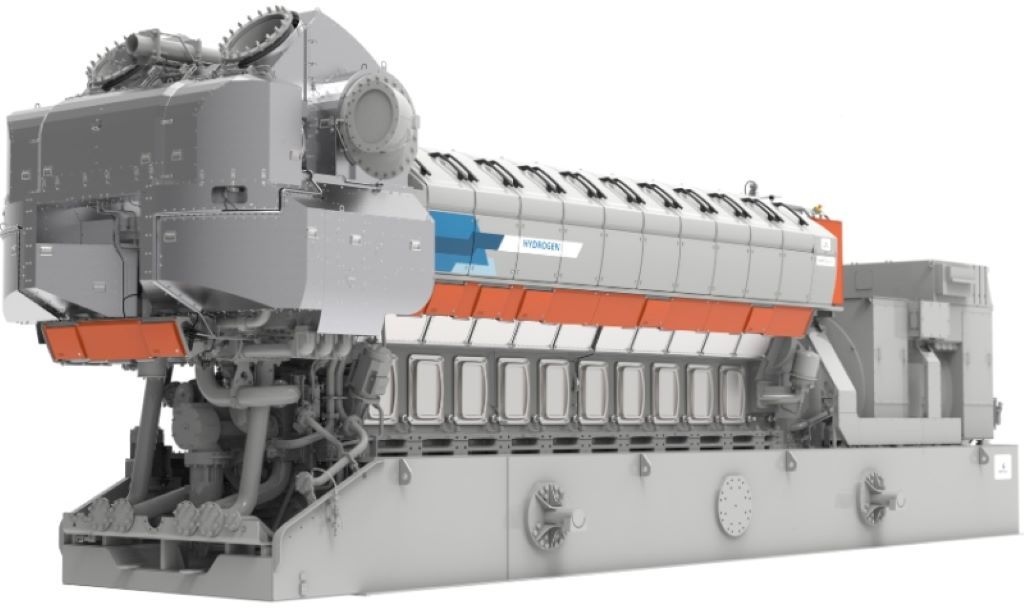

One of the largest engines in the world has been transformed into a clean generator. Originally designed to burn diesel, dual fuel or gasoline for tankers and container ships, the Wärtsilä 31 marine engine has a new life generating clean, renewable electricity.

The Wärtsilä 31 engine is in the Guinness Book of Records for being the most efficient 4-stroke marine engine ever manufactured in its class. It also boasts the highest power per cylinder in engines of equivalent diameter. It can be configured with 8 to 16 cylinders and with power output varying between 4.6 MW and 10.4 MW at 720 and 750 rpm.

This Finnish company is best known for manufacturing the world’s largest combustion engines, notably the 27 meter high, 13 meter long, 82,028 kW RTA96-C. The Wärtsilä 31 engine is considerably smaller, with a maximum of 4.7 meters high and 8.7 meters long, and running on fossil fuel, it can generate up to 9,800 kW.

The cylinder bore and stroke (31 x 43 cm) may seem enormous coming from the automotive world, but compared to some of the company’s largest engines, which have cylinders large enough to walk inside, They are relatively compact.

Converted into a generator, the hydrogen-ready 31SG-H2 can run on natural gas, or a blend of natural gas and 25% hydrogen, or can be upgraded to run on 100% hydrogen. There is also a fuel-flexible version, the 31H2, designed to run natively on pure hydrogen, but also accepts natural gas or blended fuels.

Both promise to be the world’s largest hydrogen generators when they launch, assuming there is enough hydrogen available to operate them.

The hydrogen power plant is designed to stabilize a grid based on renewable energy, rapidly increasing or decreasing its production to support intermittent clean energy sources such as solar and wind, with no minimum activation or deactivation time and with the ability to synchronize with mains power in just 30 seconds with the push of a button. By using hydrogen, Wärtsilä can generate 100% carbon-free electricity.

We must be realistic that natural gas will play a role in our energy systems for years. Our fuel-flexible engines can use natural gas today to provide flexibility and balance, allowing renewable energy to thrive. They can then be converted to run on hydrogen when it becomes available, future-proofing us on the path to carbon neutrality.

Anders Lindberg, President of Wärtsilä Energy

Wärtsilä’s power plant concept has been certified in phase 1 by TÜV SÜD, an organisation focused on protecting people and the environment and ensuring regulatory compliance. It must pass two further certifications before construction can begin. Its hydrogen-ready engines are expected to be available for delivery in 2026.

With over a million hours of operation and over 1,000 MW of installations to date, Wärtsilä has a proven track record of reliability. We’re interested in what kind of efficiency this colossal machine can achieve and how it might compare in terms of long-term economics on an industrial scale versus a large fuel cell operation, which could convert hydrogen directly back into electricity and water.

Via www.wartsila.com

If you liked this article, share it with your friends on social networks. Thank you!