Cycling continues to be a hit in our country. And not only in terms of sporting competitions such as the Vuelta a España, but in the daily lives of thousands of people who use bicycles to get around or to practice one of the most complete sports in existence. Electric bicycles are revolutionizing the sector, but Conventional bikes are not far behind in terms of innovation. Various key parts are receiving essential updates, such as the connecting rod that increases performance or tires with NASA technology to prevent punctures.

Among the key components of the bicycle, the saddle stands out, which in many cases can be a source of problems, pain and poor posture. The goal should be a weight distribution as balanced as possible and that this falls on the ischiums, the bones of the pelvis, but in many cases this is not achieved, which can even lead to injuries. To solve this, a divided and articulated saddle has recently been launched that adapts better to the body, but there are those who rely more on biomechanical studies and 3D printing to achieve unique, completely personalized saddles.

This is what fizik proposes, an Italian brand founded in 1996 whose mission “is to manufacture the most sophisticated, inspiring and beautiful equipment for the most demanding cyclists in the world,” according to their website. Their new product is called One-to-One and is the most advanced version of their Adaptive saddles, with 3D printed filling made from custom measurements after a pressure mapping session, which increases comfort across the entire surface of the saddle and improves performance with each pedal stroke.

A saddle for every cyclist

Most saddles available on the market are designed based on standard measurements, although there are specialized models in different widths and shapes to adapt to different types of terrain and riding positions. However, every body and way of riding is different, and The ideal is to adapt the bicycle as much as possible to whoever is going to ride it..

At fizik they have been researching the science of cycling performance and how to improve specific pieces of equipment for years. Their Adaptive line of gravel, road and mountain specific saddles offers extra comfort thanks to 3D printed padding.

The Fizik One-to-One saddle

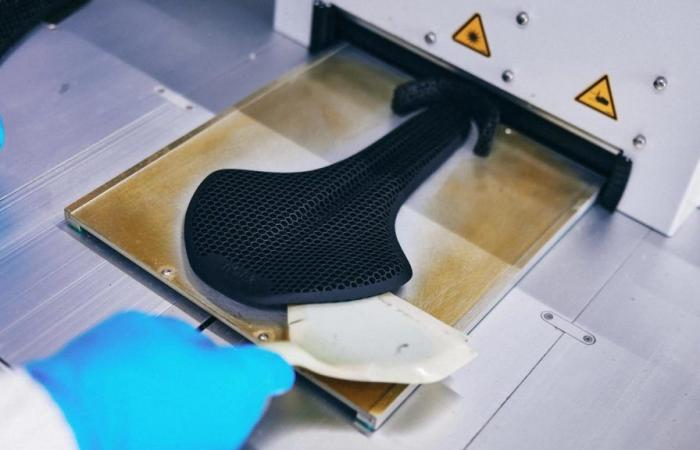

To do this, it uses an innovative process known as DLS (digital light synthesis), which takes advantage of the “digital ultraviolet light projection, oxygen permeable optics and programmable liquid resins” to “print” a comfortable padding, very resistant to both sun exposure and prolonged and repeated use.

The goal is to finely adjust where support occurs on the saddle, making it firm where responsiveness is needed and soft where pressure relief is required. Thus they manage to go far beyond the classic covers with silicone padding, offering multiple functional comfort zones in the saddle itself, which implies “a 60% reduction in maximum pressure thanks to better weight distribution“.

Fizik’s One-to-One saddle

Fizik

Omicrono

To go a step further in the comfort and optimal performance of the cyclistat fizik they have developed the One-to-One. To get this custom saddle, you need to go to one of the stores associated with the Italian company (there are none in Spain at the moment), to take part in a measurement session.

Pressure mapping

Once the measurements have been taken and a standard model from the Adaptive range has been chosen, the pressure mapping session takes place. The client has to ride a bike attached to a roller and sit on the chosen saddle, covered with a pressure-sensitive cover connected via Bluetooth to the gebioMized app. This technology allows Evaluate the pressure at 64 different points on the saddle in different movements and postures.

The cover that allows you to map the pressure on the saddle

Fizik

Omicron

Using this data, Fizik technicians are responsible for 3D printing the padded filling with a fully custom-made elastomeric honeycomb lattice structurewhich is then integrated into the Adaptive saddle chosen by the customer. In total, the process takes about four weeks from the start of the measurements to receipt of the order at the customer’s home.

Still, it is also possible to take advantage of a final pressure mapping session with the resulting saddle, to confirm the effectiveness and comfort of the final design. As for the price, it depends on the Adaptive model chosen, but The starting point is 465 euros. It may seem a bit expensive, but for a regular bicycle user, such a complete and totally personalized solution can be a before and after.

An app collects the cyclist’s pressure zones before and after the saddle is manufactured

Fizik

Omicrono

In fact, Several companies are focusing their efforts on saddles to make cycling a more comfortable and comfortable sport. Among them are solutions such as Saddle Spur, with a spur at the rear that provides a point of support to give more power per pedal stroke and to reposition the pelvic cradle, readjusting the cyclist’s support.

More recent and ambitious, the vabsRider model, from the Australian company ataraxyBSC, is a dynamic saddle with a split body that “allows individual leg movementwhich rotate around the hip joints on a virtual axis relative to the saddle.”

Thus, both pads move independently up and down along with the legs, so transfer pressure from the bones of the waist to the femurs. It is a much more logical way of distributing the weight, which is distributed evenly and without causing pain or postures that could be detrimental to the cyclist’s health.