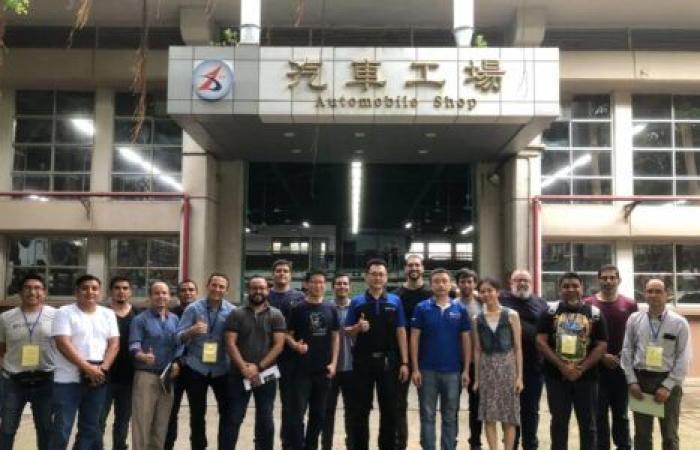

Electromechanical Engineer Gerardo Szwarc, graduated from our San Francisco Regional Faculty, recently returned from Taichung, Taiwan, where he was one of the two Argentines who took part in a training course in the operation and maintenance of electric vehicles, taught at the TCNR of Taichung. The experience took place between May 8 and June 12.

After his return, the Engineer referred to this opportunity, which was provided by the Taiwan International Cooperation and Development Fund (ICDF), an entity dedicated to promoting socio-economic development, improving human resources and promoting economic relations in a variety of developing partner countries. It also offers humanitarian assistance and provides help in the event of natural disasters or international refugee crises.

His goal is to apply what he has learned in the preparation of his doctoral thesis and share knowledge through teaching, taking advantage of the growing interest in electric vehicles.

Balance of the experience

Szwarc, who visited a country where it is common to see pure electric and hybrid cars on the road, unlike Argentina, said that the balance of what he experienced there was “very positive” as it allowed him to surround himself with and learn from highly trained people in electric vehicles, including engineers and instructors from different training centers.

Regarding the course in particular, he commented that it started with basic content, such as the use of tools, and took them to the point of allowing them to disassemble an electric vehicle in order to take measurements. Then, to reassemble it and start it up, which allowed them to gain very valuable practical experience.

The graduate of our university, who emphasized that the process had emphasized safety, since it involved working under high voltage, provided more details: “For example, we removed the computer (MCU) from an electric vehicle, we had to remove part of the engine and disassemble it. We also removed the battery from a hybrid vehicle and had to reassemble it. This allowed us to know where each component was located and where to look in case of detecting a fault. The entire process had to be carried out with dielectric gloves, insulated tools and other safety elements necessary to avoid accidents.”

Although they could not drive it, because they did not have a license from that country to do so, for the Engineer it was an enriching experience and he justified it: “Within the measurements we carried out we went from the simplest, the measurement of the 12V battery of a vehicle, to the different sensors. For example, when we work with electric motorcycles, we measure the handlebar sensors that control the acceleration, the brakes and the signal that reaches the controller. At the end of this stage of the course we will be able to measure the sensors on the handlebars that control the acceleration, the brakes and the signal that reaches the controller.They put you in front of a combustion engine of a conventional vehicle, they gave us the manual and a list of sensors, and We had to identify their position and measure them to check that they were working correctly. In the next stage, they allowed us to connect an oscilloscope to a vehicle adapted for training to check the operation, for example, of the main battery relays (hybrid car), the controller voltage, the operation of the air conditioning, water pump or the temperature of the controller, among other things.”

“Assembling and disassembling a vehicle allows us to identify its components and their location. Seeing the components on a screen does not allow us to take a true dimension of the size or weight of each of them. and it is difficult to imagine its location in the vehicle, both on motorcycles and cars,” he added.

Next, he highlighted the professionalism of the teachers. And of the other participants, he said that the majority were engineers, masters or doctors, although there were also those who did not have their degree completed, but worked as instructors in training centers and some even had their own automotive repair shops or worked in companies that were looking to venture intoelectric busesMany of those who worked alongside him work within universities as teachers or trainers in different areas, but always related to the electrical part.

Next, he added: “The teachers are very qualified, They truly have a passion for teaching.for transmitting knowledge, at no time did they see us as competition, but rather as those who tomorrow will transmit the same knowledge that they gave us.”

The graduate of our higher education institution also commented that during the training they were able to visit several companies, including the firm Master Transportation Bus Manufacturing Ltd., a factory that was previously dedicated to combustion buses and today ventured into electric vehicles, it even already exports its buses to different parts of the world.

Another company they visited was Jonnswey, which manufactures both manual, pneumatic and electric tools: “There we received training on how to use some of the tools they manufacture. There were also cultural visits organized by the same institute, in which we were able to visit iconic places in Taiwan with a lot of history and learn about their history and culture.”

Electric cars

Beyond the training, Szwarc highlighted the progress in the matter in that country and highlighted that it is common to see electric or hybrid cars circulating on the streets.

On this subject, he said: “As for pure electric cars, the most common brand is Tesla. And for hybrids, the Toyota Prius. The Prius, for example, is available in Argentina, although Tesla models, as far as I know, are not yet sold in our country.”

The graduate of our Regional also revealed how the Taiwanese government encourages the use of electric cars: “Electric vehicles do not pay taxes and they have made a commitment, by 2040, to prohibit the production of combustion vehicles of any kind, from buses to motorcycles.”

Transfer

Szwarc’s objective was achieved, as the knowledge learned can be applied in his doctoral thesis, with which he hopes to dedicate himself exclusively to research and teaching within the UTN.

“My PhD is based on solar photovoltaic energy, in the distributed generation mode, and on electric vehicles and how all this would affect the electrical distribution network, mainly the transformer,” he said.

Along these lines, he clarified that, although in Argentina there are courses on renewable energies, distribution networks and transformers, there are not the same number of courses on electric vehicles, which is why he valued the experience even more. “It strengthens my knowledge of this subject, which I had no training on,” he said.

Everything acquired can also be reflected in the classrooms, since as the years go by more electric vehicles will be found: “Taiwan is already considering that for There will be no more combustion vehicles by 2050. There will be very few left. Once they fail the inspection, the equivalent of our MOT, they have to be destroyed or sold to another country that accepts them.”

“In Argentina, although the production of combustion vehicles is not scheduled to stop, sooner or later it will comeso at some point training will be necessary, because the maintenance done on an electric vehicle is not the same as that of a hybrid or combustion vehicle,” he added.

Finally, he acknowledged: “I would like to thank all those people who in one way or another accompanied me on the trip., from those who were simply in contact, to those who were attentive to ensure that I did not miss anything. Also to those who helped me organize everything and prepare the documentation I needed to be able to make the trip and accompanied me in the process. I also want to mention the organizers, the ICDF and TCNR, for everything they made available to us, from the opportunity to the teachers and the material necessary to carry out the practices.”