Lithium ion battery technology is one of the most used in our daily lives. They are present in smartphones, but also in laptops, headphones, electric cars or wireless DIY tools that are used daily in Spain. Although their capacity and durability have greatly improved in recent years, they still take up considerable space, are dangerous andyes difficult to further increase their energy density to make them less heavy.

To solve this problem, companies and scientists are betting on solutions such as gravity batteries in buildings or manufacturing materials capable of accumulating energy directly in the casing of the devices themselves. Along these lines, one of the most promising investigations has to do with the properties of carbon fiber to store energy electrochemically and act as electrodes after a complex manufacturing process.

This is what the Swedish startup Sinonus is working on, a spin-off from Chalmers University of Technology in Gothenburg, which has just announced its intention to commercialize this material to power all types of devicesstarting with small sensors but with an eye on drones, computers, cars and even wind turbine blades or buildings.

Carbon fiber

As those responsible for Sinonus explain on their website, it is common to build structures and casings with single-use materials. In the case of carbon fiber, it is highly appreciated in industries such as space, aeronautics or automobiles, thanks to its high mechanical resistance and low density.

As for batteries, they are essential for the operation of countless devices and one of the keys to the electrical and renewable energy revolution, but they normally only fulfill that storage function. “From the point of view of effectiveness, One-time use comes at a cost in volume, weight and overall system performance“, they maintain in Sinonus.

Sinonus Carbon Fiber Diagram

Sinonus

Omicrono

Thanks to technology developed by Oxeon, also dependent on Chalmers University, and responsible for elements such as the rotor blades of NASA’s Ingenuity helicopter (which has said goodbye on Mars after 72 missions and far exceeding its initial objectives), Carbon fiber can offer both functions: structural strength and energy storage.

To achieve this, Sinonus technicians have taken advantage of the structural resistance of carbon fibers and their electrochemical properties to act as electrodes in a battery cell, in conjunction with a specially developed electrolyte to ‘close’ the circuit. This achieves the objective of “making light and structurally strong constructions with an integrated electrical storage capacity”, which are also safer than lithium ion batteriesdangerous because they are highly flammable.

Practical applications

As the first use of this material, the Swedish company has successfully replaced AAA batteries in small devices that require low power by carbon fiber with satisfactory results. “Storing electrical energy in carbon fiber may not be as efficient as traditional batteries, but since our carbon fiber solution also has structural load capacity, very large gains can be obtained at the system level,” he explained. Markus Zetterström, its newly appointed CEO, in the online medium Recharge.

Now the challenge is to scale and improve the technology to adapt it to more voluminous elements and systems with greater energy needs. One of the great objectives is the wind turbine blades, usually made of carbon fiber. Thus, in addition to generating large amounts of energy at times when the wind blows, these gigantic structures could also store it to overcome one of the main problems of renewable energies, their intermittency.

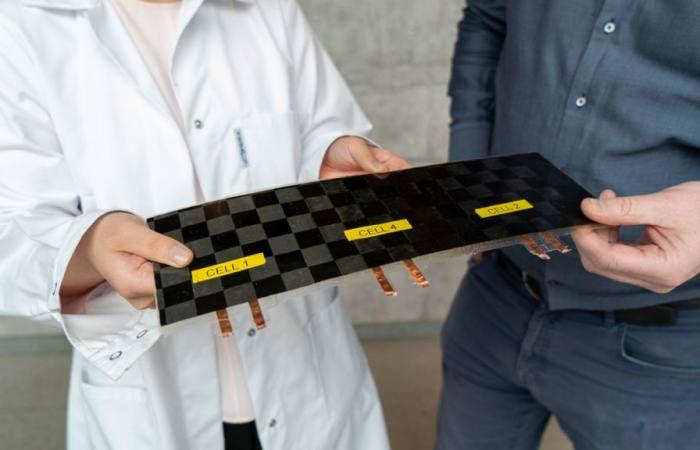

A carbon fiber sheet with energy storage properties

Sinonus

Omicrono

Its potential is also enormous in the automotive, nautical or aeronautics sector. Carbon fiber is common in these industries, and would be a way to lighten the load of huge lithium-ion batteries, which can sometimes account for 50% of the weight of an electric vehicle. Precisely, research from Chalmers University came to the conclusion that Reducing the weight of batteries in electric cars and boats could boost their autonomy up to 70%.

Zetterström went further, and in addition to talking about wind turbines, cars, ships and airplanes, he even ventured to predict that, in the future, the buildings themselves could have carbon fiber structural elements that served as large-scale battery systems.

Supercapacitors

Carbon fiber has enormous potential in this area, and had already provided significant advances in the field of supercapacitors, which are able to store and release energy very quickly. They are a very attractive alternative to conventional batteries, since theyyes The materials that make them up are common (aluminum, carbon, cellulose, polymer…), which means giving up lithium and other components that are difficult to recycle.

One of the latest developments in this field comes from a team of researchers at the University of California, San Diego, who have developed a structural supercapacitorcapable of providing both structural support and energy storage capacity.

The hull of a small ship covered in supercapacitor material

David Baillot / UC San Diego

Omicrono

To get it, They made the electrodes with carbon fibers intertwined in a fabric, coated with a mixture of conductive polymer and reduced graphene oxide. These materials significantly improve the flow of ions and, therefore, increase the storage capacity.

The other fundamental component of this new supercapacitor is the solid electrolyte, obtained from the union between an epoxy resin and polyethylene oxide, which gives the material greater structural support and favors the mobility of the ions. To demonstrate and test the capabilities of their find, engineers used it to build the hull of a simple solar boat. Once molded to the shape of the boat, a small motor was installed to propel itself and a circuit connected to a photovoltaic cell.

Lulu Yao, doctoral student in Materials Science and Engineering and first author of the article published in the specialized journal Science Advances, considers it as a key first step in a much more ambitious investigation. “Our future work will focus on increasing the energy density of our supercapacitor until it is comparable to that of some batteries. The ultimate goal would be to achieve both higher energy and power density.”