A little more than a year after the start of the investment, the Pinar del Río silica sand plant, belonging to the Company Geominer of the territory, it still does not look like what it should be.

In some of its areas there are still men who dismantle metal structures badly damaged by corrosion, and then change them, and in others the rust of four decades is cleaned with specialized machines and a crane that lifts them more than a dozen meters from the floor.

The roof of one of the two warehouses is missing, along with a long stretch of the water pipe, the mats and screens, and the process plant.

However, engineer Leonel Valdés assures that the 23 containers located in the industry yard contain everything that is needed to complete its capital repair.

«There is nothing that can stop us. All the equipment you need is already here,” he says.

With a cost of five million dollars and 35 million pesos, the investment includes the total change of the technology, which already showed a marked deterioration. In addition, the rehabilitation of the railway branch through which production is transported, the tail dam where waste is deposited, the administrative buildings, the laboratory, the workshop…

Leonel points out that, when it is completed, the plant will once again have a production capacity of 280,000 tons of silica sand per year, the same as when it was inaugurated in October 1984.

The main destination will be the production of glass in the Mariel Special Development Zone (zed), where approximately 38,100 tons per year will be demanded initially, and the figures are expected to increase, reaching approximately 76,000.

However, the Pinar del Río plant, located in the municipality of Guane, will be able to provide that and more. Hence, after the investment process, it is necessary to look for other clients dedicated to the production of glass or other applications that silica sand has.

THE RENAISSANCE OF THE INDUSTRY

It all started at the beginning of 2023. Leonel points out that, by then, deliveries had declined to around 30,000 tons per year, due to the poor condition of the equipment and the drastic decrease in demand from the Cuban glass industries.

This would force them to resort to multiple alternatives to survive and not lose their specialists and the workforce in general.

“We began to venture into the production of sand for construction, cement mortar for fine and thick plaster, products for soil improvement in agriculture and even bleach and vinegar.”

The specialist remembers that, although the plant continued to operate, the deterioration was widespread, due to years of operation and lack of maintenance; Therefore, the sand no longer had the same quality as in other times.

It is in this context that, based on a project to promote the production of glass containers in the ZED, it was decided to carry out capital repairs.

The planned actions include a complete technological change. That is, the replacement of pulp pumps, screens, hydrocyclones, vibrating drainers, sand conveyors.

The process also includes the replacement of metal structures that no longer meet the technical parameters, both in the processing plant and in the warehouses, the rehabilitation of the two railway branches of 0.8 kilometers each, the cleaning the tail dam basin and the construction of a retaining wall and a mud conveyor.

Among the novelties of the new technology, the engineer highlights the possibility of recycling the water used in the industrial process, using equipment that clarifies it again.

On the other hand, it states that the installation of solar panels on the roofs of the socio-administrative buildings is planned, with a generation capacity of 43 megawatts per year, in order to compensate for the energy they consume.

The specialist says that in 2023 work was carried out on the importation of technology and equipment for the laboratory, including reagents, and also other support means, such as pipes for water and fuel, forklifts and a crane.

The actions undertaken so far include the waterproofing of the roofs in the office area and the laboratory, the machining workshop, and the roofing of one of the two 60-meter-long warehouses.

In addition to this, the first 800 meters of the four-kilometer pipeline that will supply water to the industry from the Cuyaguateje River have already been located.

«THING NEW IS NEW»

If everything goes as planned, Leonel affirms that towards the month of October the final touches will be given for the start-up, and that high quality silica sand will once again be obtained, suitable to satisfy the demand of the different national clients. and even for export.

The studies carried out show that only with Zed Mariel the investment can be recovered within a period of three to four years. “If we manage to add other clients, that time would be reduced and that is precisely what we need,” he says.

A field with proven reserves for 25 years and others that could be incorporated from the studies that are underway, guarantee a long life for this valuable industry, when the work is completed and production is restarted.

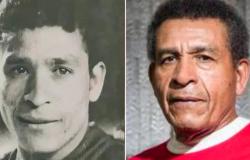

For José Antonio Valdés, one of the workers who has been here since its construction 40 years ago, this is excellent news that will restore vitality to a facility to which he has dedicated most of his life.

“I have spent more time here than at home, and I don’t regret it, because I like working with irons,” he says.

Engrossed with his brigade in assembling the new technology, he confesses that after so much time one ends up becoming fond of each element that is now discarded and that for decades he had to “mechanize” to keep it up to date.

However, he warns that one cannot go against development. «The plant we had was very good, but it was already too deteriorated. And this one that we are going to install is also good. I already saw it in the containers. They are magnificent teams. Furthermore, new is new.

|