The new RAM memories The CAMM2 standard was one of the highlights of Computex 2024, attracting attention for its different format and specifications. Several companies presented products already with new souvenirs. In Kingston, they reserved a good part of their stand to show what changes in the new format and how it positively affects manufacturers and consumers.

Photo: iFixit / Playback / Canaltech

The initial highlight is the possibility of new memories replacing the LPDDR modules soldered to motherboards. With this it will be possible to perform memory upgrades in systems where, until now, this was not an option.

In addition, the technical project also brings a series of changes to improve performance on different fronts, instead of simply accommodating more NAND chips, since the new format limits this possibility.

What are the new CAMM2 RAM memories like?

In current DDR standards, the pinout is at the “edge” of the PCB, with the chips, microcontrollers, and other components distributed along one or both sides of the board, depending on the design, requiring that the board connector base is, to some extent, vertical.

Traditional DDR memories have pins on the edge of the PCB, creating vertical connectors, but difficult to accommodate in compact systems (Image: G.SKILL / Disclosure).

Photo: Canaltech

Not specifically in the case of notebooks, the solution to take up less space is to use articulated connectors, which fix the Memory Sticks at a very steep angle, almost lying down. Still, this limits some more compact designs, such as ultra-slim and portable consoles.

Slimmer physical design

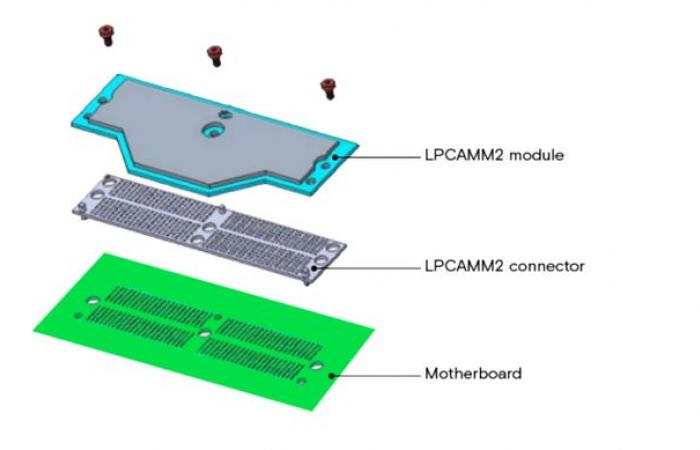

The first notable change in new CAMM2 memories is, of course, the arrangement and shape of the connectors, no longer on the edge, but at the bottom of the PCB. As a result, the hardware stops being vertical and becomes horizontal and flat, with smooth metal contacts, in an extremely thin design.

The new CAMM2 format reduces the vertical profile of the memories to a few millimeters. (Image: Micron / Reproduction)

Photo: Canaltech

The choice of smooth contacts instead of the pins themselves prevents the memories or the motherboard connector from being damaged by deformations resulting from impacts, small vibrations during transport or during the installation of the components themselves.

The modules are fixed to the motherboard using 5 star screws (Philips) with small “cradles” in the perforation, similar to those of M.2 SSDs. In this way, even ultra-thin and portable consoles can do without modules soldered to the motherboard, guaranteeing the possibility of upgrades in an ultra-compact format.

More efficient communication with the CPU

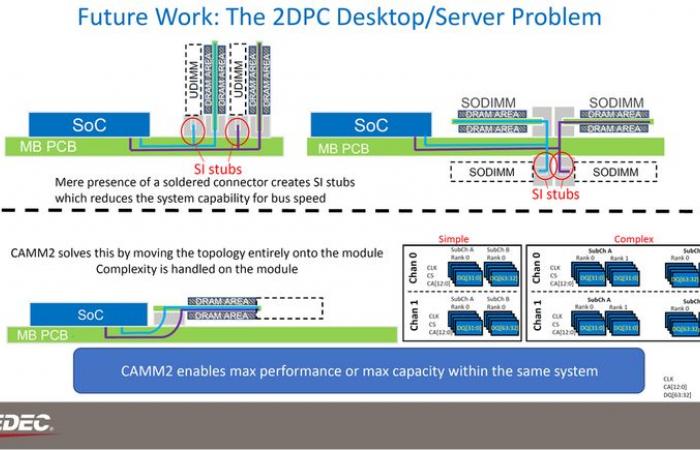

Naturally, the reduced form factor alone would not justify investing in a completely different memory standard. Traditional DDR standards benefit greatly from the scalability factor as they are easily replaced, but to be viable they depend on microcontrollers and other components that mediate communication with the processor.

This distance and larger steps in the CPU’s access to memory limit the speed of instruction execution and, consequently, system performance. These access times are what we call latency in memory specifications, and emphasizing transfer rates by overclocking memory improves maximum speed but hurts access times.

The flat connector format shortens the paths between the memory and the CPU modules. (Image: JEDEC / Reproduction)

Photo: Canaltech

At the same time, LPDDR memories, soldered to motherboards, have more direct communication paths with the processors, offering much lower latencies. More than the reduced profile, this is one of the main reasons why many manufacturers opt for LPDDR memories in their projects.

The new CAMM2 memory standard considerably shortens the distance between the memories and the UPC, and increases the communication surface with the new connectors. In this way, they provide much shorter access times and support faster transfer speeds, even without overclocking, all without compromising upgradeability.

Integrated dual channel

Another important difference is that modern systems use parallelism to increase computational efficiency and, for this reason, working even with memory channels is very important. The problem is that in current standards each channel requires a dedicated connector, with different distances for each channel, independent controllers, and all this directly affects access times.

The dual channel integrated into a single flat connector improves performance and facilitates the validation process. (Image: JEDEC / Reproduction)

Photo: Canaltech

In the new CAMM2 standard, the two memory channels are integrated into the same connector closest to the CPU, and with a single controller. This greatly optimizes access times, but also makes the project easier for the manufacturers themselves.

By working with a single connector with two integrated memory channels, you can optimize the connector and memory validation process. This is because it is no longer necessary to validate each connector independently and then validate the entire assembly to determine memory speeds and latency depending on whether the arrangement has one, two or four sticks.

Positive and negative points of CAMM2

Like any new technology, the initial production cost also ends up being higher, and this is inevitably passed on to the final consumer. oh canaltech was at Computex 2024 and motherboard manufacturers suggested that the idea is for CAMM2 modules to follow a price range close to that practiced in the DDR standard, but some increase, however small, is inevitable.

If the technology takes hold, research and production costs will end up diluting over the years, but, at least initially, CAMM2 memories should be relatively more expensive than DDR5 memories.

Positive points

- The horizontal profile allows replacing soldered LPDDR memories

- Modularity for easy upgrade

- Proximity to the CPU reduces latencies

- Single connector makes development and validation easy

Bad points

- More expensive to produce

- Lower maximum memory density

- Scalability limited by motherboard size

- Installation is more delicate and uses screws.

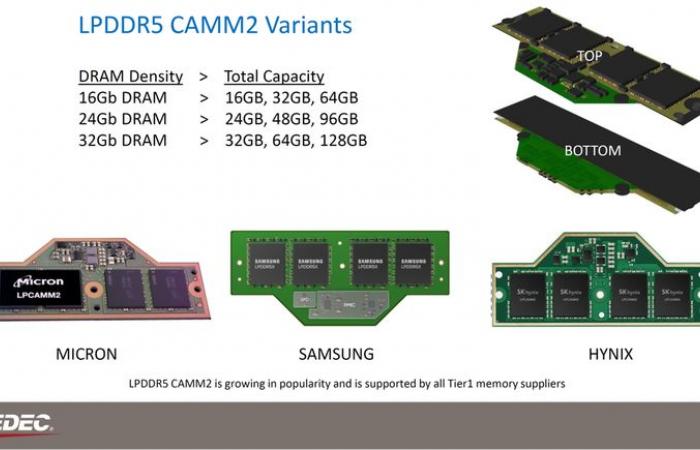

DDR combs allow you to use both sides of the PCB to accommodate chips and other components when necessary. So much so that Micron has already confirmed that it is working with combined technologies that will soon make Scalable memories viable up to 1 TB per memory card.

However, depending on how these technologies are implemented, this level of scalability would no longer be viable on laptops, or even desktop computers. Therefore, improving performance by focusing on elements other than the density of NAND chips is a more interesting solution.

In the case of CAMM2 memories, more of the bottom of the PCB is used to house some controllers and the flat connector, reducing the total area available for the NAND chips. Initially, the density of the first models ends up being higher, with a single module having capacities of up to 128 GB.

On the other hand, long-term scalability is limited to expanding the surface of the entire comb, compromising a greater surface area of the devices’ motherboard, and being a potential problem in the medium term.

When will CAMM2 memories be released?

According to what the canaltech According to what was surveyed at Computex, the first memories are expected to hit the market in the third quarter of 2024, with 32 GB, 64 GB and 128 GB modules. Initially, Only ADATA, which is also a memory manufacturer, has already confirmed a portable console with the new CAMM2 standard.

In the laptop sector, Lenovo has already launched the first ThinkPad P1 Gen 7 with replaceable CAMM2 memories, but there is still no date for the model to arrive in Brazil. On the desktop side, some motherboard manufacturers brought boards with CAMM2 to Computex for the new processors. Intel Arrow Lake, but without providing deeper technical details.

However, the price range has not yet been revealed, but it is important to remember that the cost of manufacturing NAND chips has been undergoing several readjustments sequentially, making several products more expensive, from microSD cards to memories and SSDs.

Trends without Canaltech: